The Advantages of Sintering With a S.M.A.R.T. Furnace

Sintering is a thermal treatment process in which a powder or a porous material, already formed into the required shape, is converted into a useful article with the requisite microstructure. Sintering can be classified as solid-state, viscous, liquid-phase, and pressure-assisted (or pressure) sintering. This article provides information on the.

Tahu Metalurgi SINTERING

Sintering is a manufacturing process that converts porous materials into less porous solids, when the material is subjected to pressure and heating.

Thermal Debinding and Sintering 101 Desktop Metal

Metode yang umumnya digunakan adalah sintering, pelonggaran, track-etching, leaching, inversi fasa. (Wenten dkk, 2011). Proses casting sederhana menggunakan pisau pencetak untuk mencetak larutan Polimer menjadi membran yang diinginkan. Teknik preparasi casting sering digunakan pada skala laboratorium. Teknik casting juga dapat dibantu oleh alat.

Pengertian Proses Aglomerasi Sintering Dalam Metalurgi Serbuk

Penyinteran adalah proses dari memadatkan dan membentuk sebuah massa material yang kuat melalui panas atau tekanan tanpa melelehkan benda tersebut hingga titik pencairan. Arti dari penyinteran menurut KBBI adalah proses menjadikan hampir meleleh sehinga membentuk massa yang menyatu.. Sintering (edisi ke-1st). Oxford: Elsevier, Butterworth.

Sintering Eurotherm Limited

Catalyst sintering is an undesired, but general, and hence practically important catalyst deactivation process. Understanding sintering kinetics and, then, the associated mechanism(s) is an important goal, one crucial to being better able to limit and otherwise control catalyst sintering rationally. However, and despite the availability of atomic-based sintering models, the kinetics of.

Thermal Debinding and Sintering 101 Desktop Metal

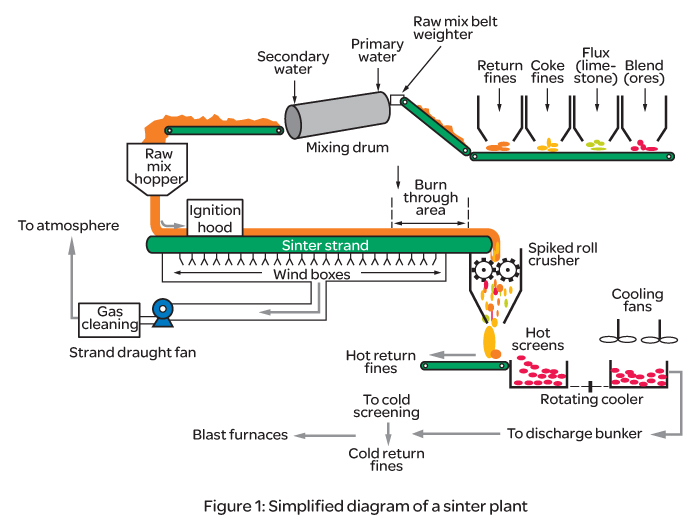

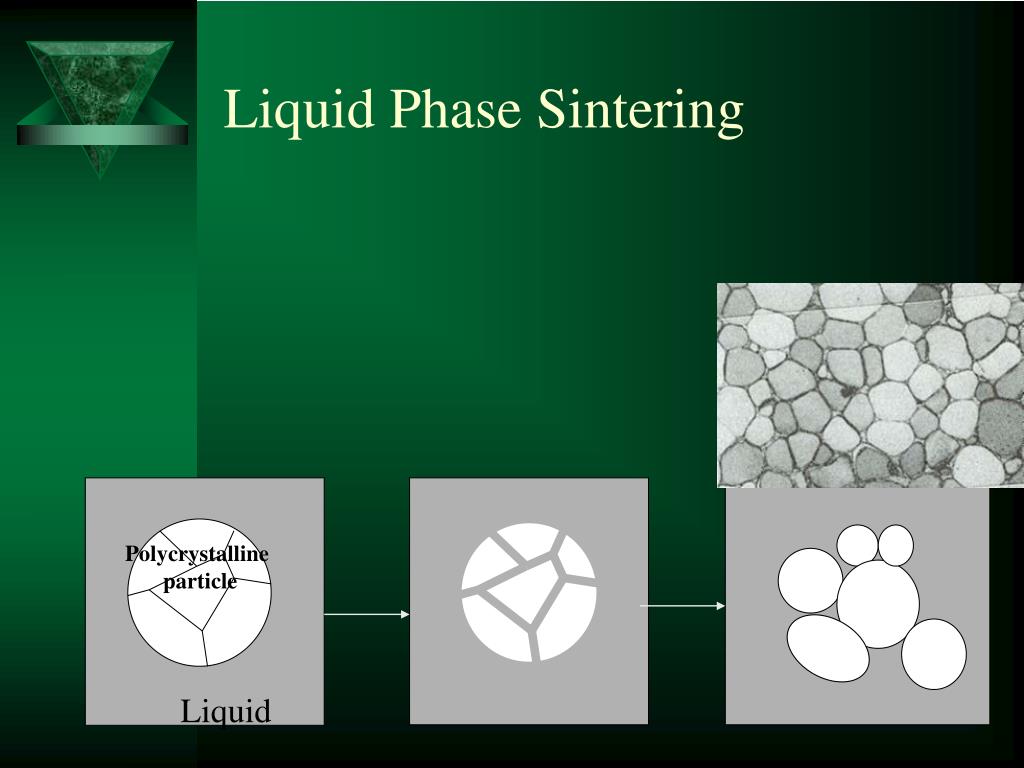

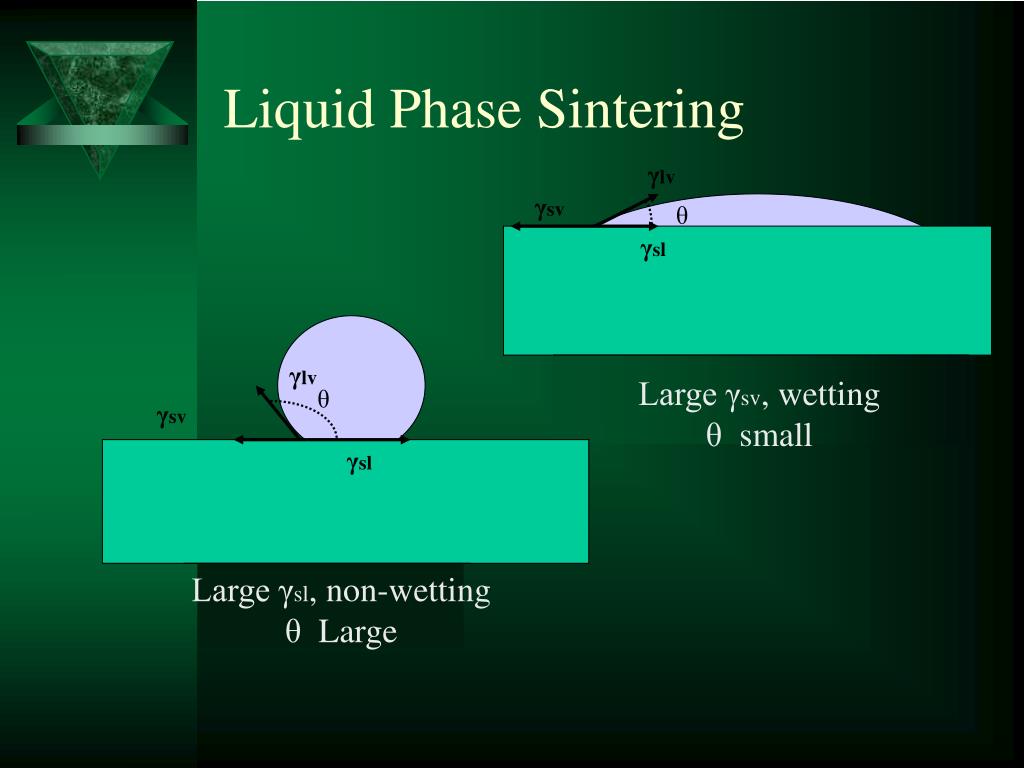

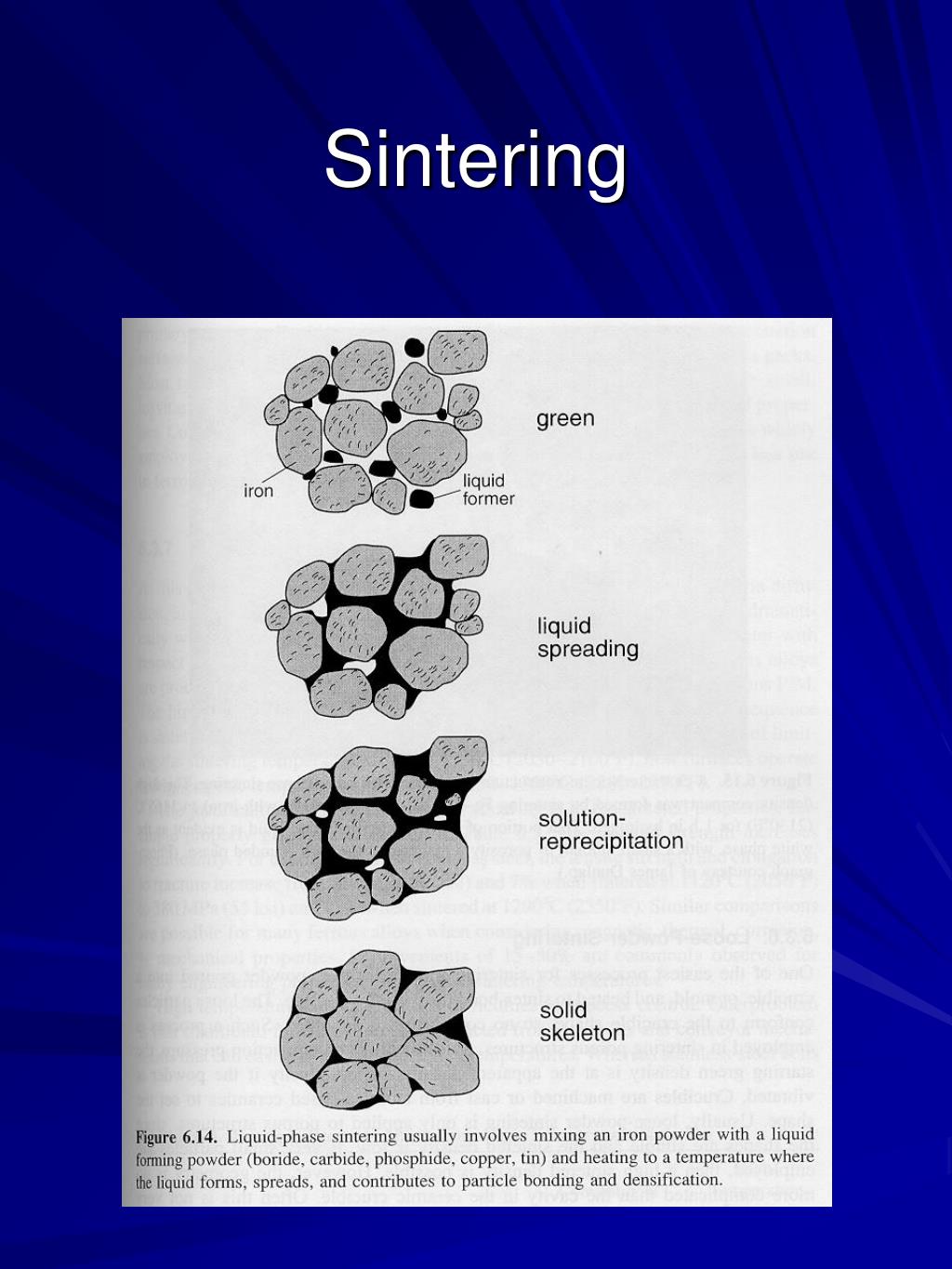

sintering occurs in an A-B powder compact with composition X 1, while at temperature T 3, liquid phase sintering occurs in the same powder compact. In addition to solid state and liquid phase sintering, other types of sintering, for example, transient liquid phase sintering and viscous flow sintering can be utilized. Viscous flow sintering occurs

Sintering Wikipedia

Sintering, which is also called 'frittage,' is the process of forming a solid mass of material through heat and pressure without melting to the point of liquefaction. This process involves the atoms in materials diffusing across the particle boundaries and fusing together into one piece. Sintering occurs naturally in mineral deposits, and.

PPT [Sintering] PowerPoint Presentation, free download ID3866196

Spark plasma sintering ( SPS ), [1] also known as field assisted sintering technique ( FAST) [2] or pulsed electric current sintering ( PECS ), or plasma pressure compaction ( P2C) [3] is a sintering technique. The main characteristic of SPS is that the pulsed or unpulsed DC or AC current directly passes through the graphite die, as well as the.

PPT [Sintering] PowerPoint Presentation, free download ID3866196

Sintering is a broad family of methods that forms integral and potentially highly complex parts from a wide range of materials, by compressing and then fusing powders and binders. The part goes through two stages. The first stage makes the required shape a weak and poorly integrated, oversize component. The second stage bakes that component to.

PPT Powder Metal Processing PowerPoint Presentation, free download ID6866507

Pengertian Proses Sintering - Sintering merupakan proses pemanasan dibawah titik leleh dalam rangka membentuk fase kristal baru sesuai dengan yang diinginkan dan bertujuan membantu mereaksikan bahan-bahan penyusun baik bahan keramik maupun bahan logam.. Pengertian Proses Sintering. Proses sintering akan berpengaruh cukup besar pada pembentukan fase kristal bahan.

Proses Sintering Pada Metalurgi Serbuk ETSWORLDS

Spark plasma sintering (SPS) is a rapid technique. Its processing parameters are usually low-voltage and low-pressure acting, using a uniaxial force and pulsed direct current (DC) to carry out high efficiency consolidation of the powder. This technique has been widely applied for various materials processing in the recent years.

Sintering process (Animation) YouTube

Sintering is generally defined as the combination of two or more nonmelting compounds. The resulting microstructures or high sample quality depend on sintering temperature, time, particle size, the heating and cooling rate of the device, the ratio of the elements blended with the sample, and the sintering furnace atmosphere..

PPT Powder Metallurgy PowerPoint Presentation, free download ID1206200

So sintering is a comprehensive procedure in which the physicochemical properties of ceramic materials are constantly changing in real-time [54]. In addition, it can be concluded that the sintering mechanism of ZrO 2 is essentially the interaction between densification and grain growth. The main operating parameters involved in the sintering.

Selective laser sintering manufacturing Britannica

Sintering is a process of compacting and forming a solid mass of material by heating it to a temperature below its melting point. This process is commonly used in the production of ceramics, metals, and other materials. The word sinter comes from the German word "sintern," which means "to heat without melting.".

12 Schematic diagram of sintering process. Download Scientific Diagram

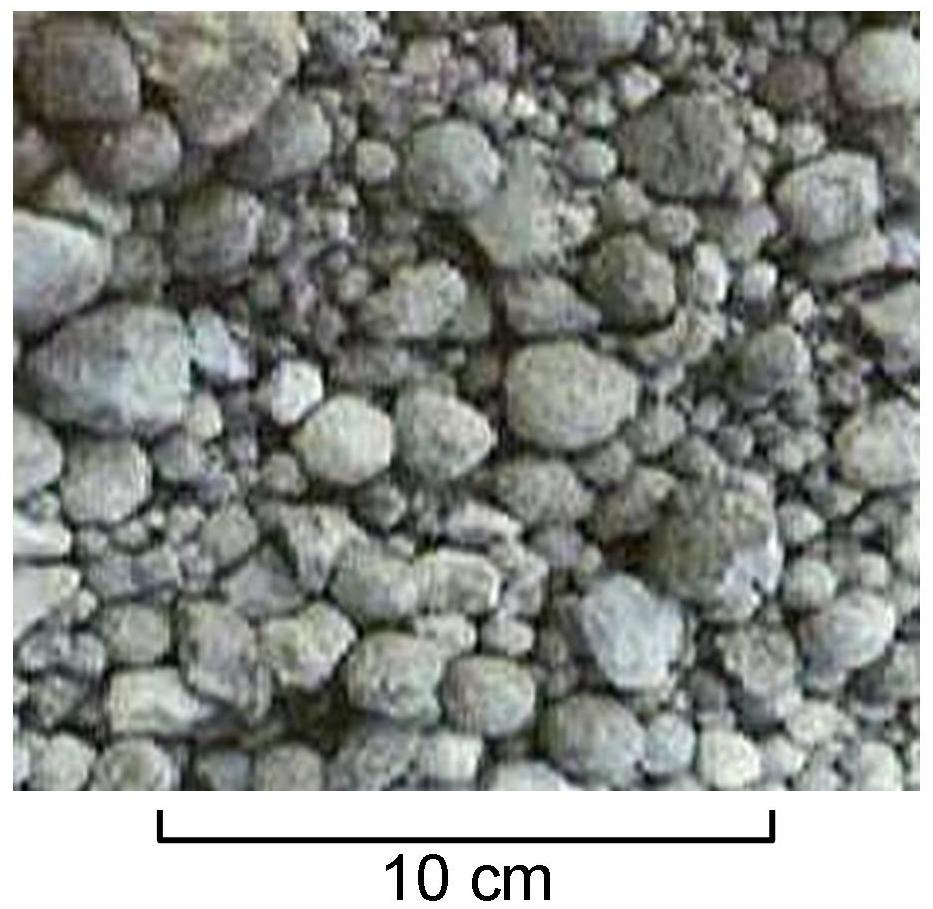

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure [1] or heat [2] without melting it to the point of liquefaction. Sintering happens as part of a manufacturing process used with metals, ceramics, plastics, and other materials. The nanoparticles in the sintered material diffuse across the.

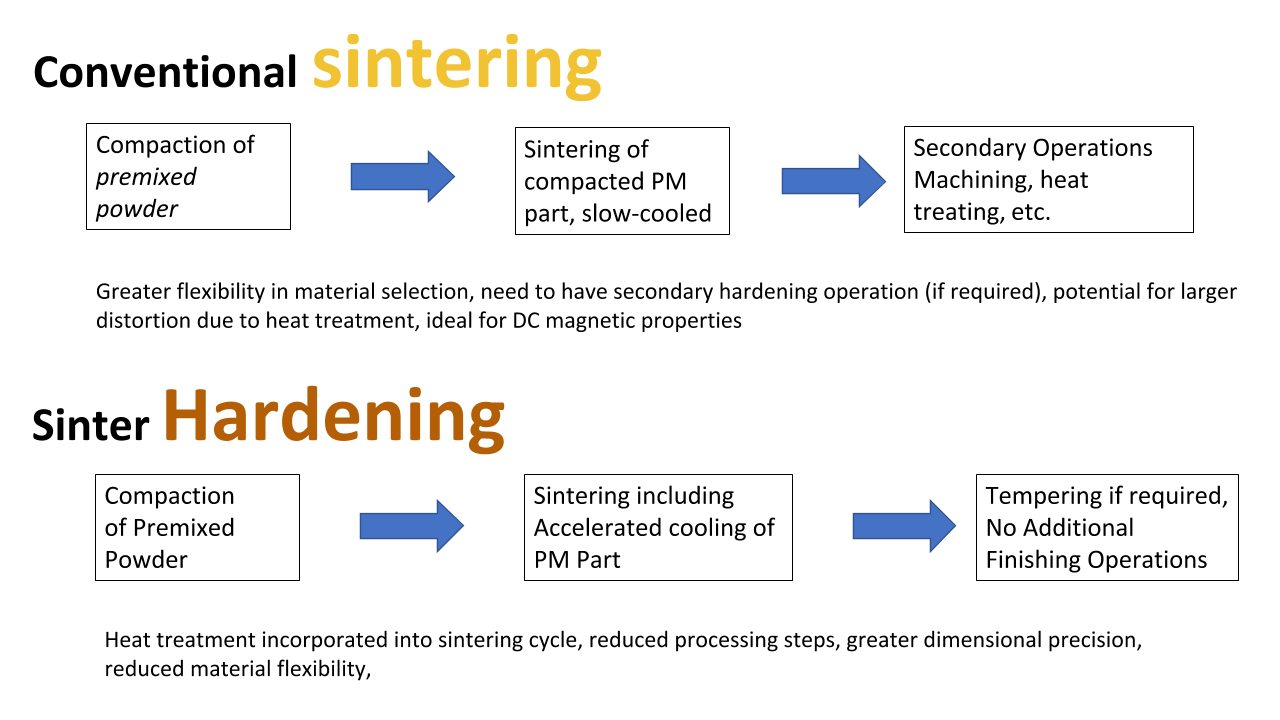

Skipping Steps Sinter Hardening vs. Conventional Sintering Processes

1. Sintering overview. The term sintering basically defines a process of bonding, densification and/or recrystallization of powder compacts, i.e. a treatment in which a green-body is converted to a stronger monolith [1], [2], [3], [4].While ceramic artifacts found in archaeological sites indicate sintering practice even in the upper Paleolithic era, i.e. specifically Gravettian around 26,000.