Plastic Molding

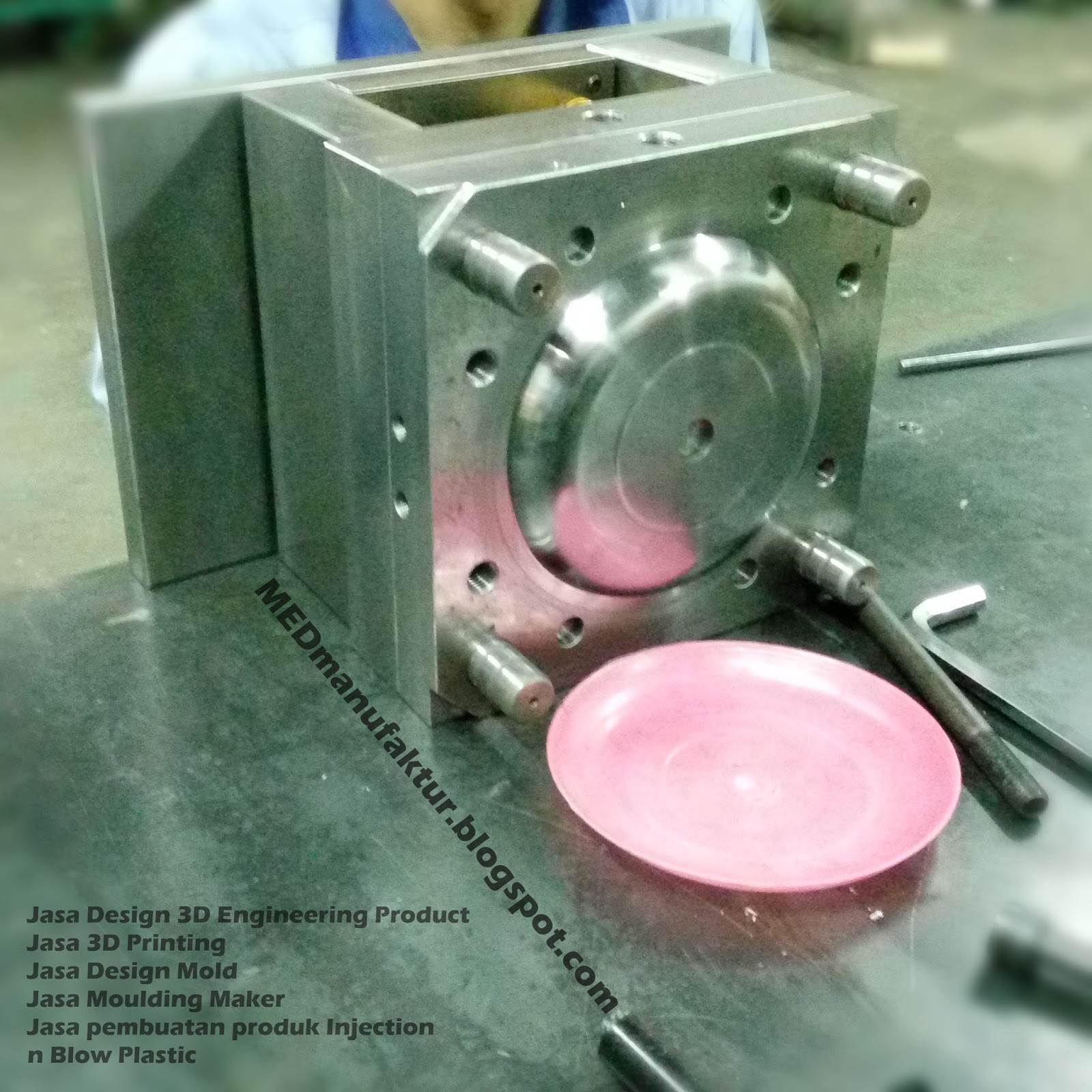

Jasa pembuatan molding plastics / plastic / plastik kami hadir mulai dari di Jakarta, Bekasi, Cikarang, Karawang, hingga Tangerang. Percayakan kepada kami PT Limaputra Contrindo terkait kebutuhan jasa injeksi / injection plastics / plastic / pembuatan molding Anda. Silahkan hubungi tim marketing kami di : 0822-6045-5410.

What is Plastic Injection Molding? Our Comprehensive Overview

Year founded: 2002. Number of employees: 1116. Key products: plastic molds. PT VS Technology is a plastic molding company located in Cikarang West Java. it was founded 19 years ago by V.S Holdings Limited and V.S Industry Berhad. It has a land area of 25,406 square meters and a factory area of 21,000 square meters.

Plastik Enjeksiyon Animasyon Plastic Injection Molding YouTube

Alat plastic injection molding dapat mengurangi limbah plastik untuk dapat didaur ulang menjadi barang baru, dimana plastik dilebur hingga mencair dengan menggunakan elemen pemanas band heater.

Gambar Mesin Injection Plastik 43+ Koleksi Gambar

1. 40 injection moulding machines, ranging from 100t to 500t and still expanding to 850t. 2. Partnership with blow injection factory, they provide Blow/Stretch Injection machines, able to produce plastic containers ranging from 20 ccs to 30 liters, Equiped with the latest technology and consumer needs such as Visi-Strip Bottles , PET processing. 3.

Understanding Plastic Injection Molding Volumes The Rodon Group®

There are several reasons for choosing these materials, ranging from increased tensile strength to durability. ABS injection molding is one of the most popular plastic injection molding processes available today. During this process, liquefaction occurs at 221°F. Then the ABS plastic cools down and is subjected to the heating process again.

Investment into new 250 Tonne Plastic Injection Moulding Machine Malton Plastics

Plastic injection molding is a manufacturing process for producing plastic parts in large quantities. It is most commonly used in mass-production processes where the exact part is being created thousands or even millions of times in succession. The process works by melting plastic resin pellets and injecting them into a pre-made plastic.

CARA KERJA MESIN PLASTIK INJECTION YouTube

Berlokasi di Pasuruan, Jawa Timur, Indonesia, kami memiliki mesin injection plastik mulai dari 90-1400 ton. Layanan yang kami sediakan berupa penitipan cetakan maupun pemesanan cetakan sesuai kebutuhan pelanggan. Kami mampu memproduksi proyek cetakan injeksi plastik kecil, yang membutuhkan presisi dan toleransi yang ketat. Kami memiliki.

CERITA CERDAS Injection plastik

Injection moulding is the primary method for creating plastic parts, components and products. Plastics are by far the most common materials that are produced using injection moulding. The process is simple in principle; a plastic material (usually called a resin) is melted and forced into a mould via injection.The mould, which usually comprises two or more pieces depending on its complexity.

Plastic Injection Molding Definitions and Benefits of Using It TechBullion

Plastic injection molding is a manufacturing process that produces high-volume plastic parts and components. It utilizes a hydraulic or electric machine, which melts, injects, and sets plastic into the metal mold fitted into the machine. There are countless reasons why plastic injection molding is one of the most popular manufacturing options.

Plastic Injection Molding Injectionmolding Vietnam, your manufacturer and fabrication partner

ABOUT PRESISI. Since its establishment in 1983, Presisi Group has established itself as a leader in Indonesia's mold making and plastic injection molding industry. Our philosophy emphasizes continuous improvement aimed at stimulating dynamic, prudent, and sustainable growth through effective management of our human and industrial resources.

Components of Plastic Injection Molding

Yuniko is a Korean-owned operating company, specializing in Plastic Injection Moulding since 2005. With many years of experience in the injection moulding business, PT. Yuniko has become one of the leading plastic injection moulding manufacturers in Sidoarjo, Indonesia. Our experienced professionals are providing high quailty and cost effective.

Jasa pembuatan plastik injection molding via online

Injection molding is a method for manufacturing high-volume parts with plastic materials. Due to its reliability and flexibility in design options, plastic injection molding is used in many industries, including: packaging, consumer and electronics, automotive, medical, and many more. Injection molding is typical for manufacturing plastic.

The Top 5 Plastic Injection Molding Defects (and How to Solve Them)

PT Injeksi Plastik Pasifik is a manufacturing company engaged in plastic injection. PT Injeksi Plastik Pasifik was founded in 2020 with the principles of hard work, continuous improvement, productivity to be able to meet customer needs for quality, price and delivery.

This is the Best Explanation of Plastic Injection Molding That You've Ever Seen SolidSmack

It's an ideal manufacturing process for industries like medical devices, consumer products, and automotive. Our plastic injection molding process produces custom prototypes and end-use production parts with lead times as fast as 1 day. We use aluminum molds that offer cost-efficient tooling and accelerated manufacturing cycles, and stock.

PROSES PENCETAKAN PRODUK PLASTIK ASESORIS HANG TAG/GANTUNGAN PAKAIAN DENGAN MENGGUNAKAN

For Dim 2, the mold dimension will be: 200./.98=204.08 mm. See Figure 2. Figure 2: Mold dimension to receive nominal part dimension. Dimensions of the cavity in the mold are fixed so shrinkage will be calculated from these dimensions. On our simple part, each dimension can reach the tolerance limits.

Plastic Injection Molding Rajawali Multiplastindo Jaya (RMJ)

The injection molding process cycle is quite short, usually lasting between six seconds and two minutes. The process consists of the following stages: Clamping: Prior to the injection of the heated plastic material into the mold, the two halves of the mold must first be securely closed by the clamping unit. The tremendous force of the clamping.