MIG vs TIG Welding Why a MIG Welder is More Efficient

Speed. In terms of speed, MIG welding is the winner because it can run constantly for longer periods. TIG welding, on the other hand, is much slower because of its huge focus on details. Of course, this is a great attribute but it affects the speed and makes it unsuitable for high production rates.

Tig Vs Mig Welding change comin

The process involves a wire that feeds out of the welding gun. A spark comes from the end of the wire. MIG welding is a more point-and-shoot process. It's great for thicker metals. MIG also suits larger projects that need long continuous welding runs. It is perfect for projects using sheet metal.

Laser Welding Versus Arc Welding Comparing Laser Welding to MIG and

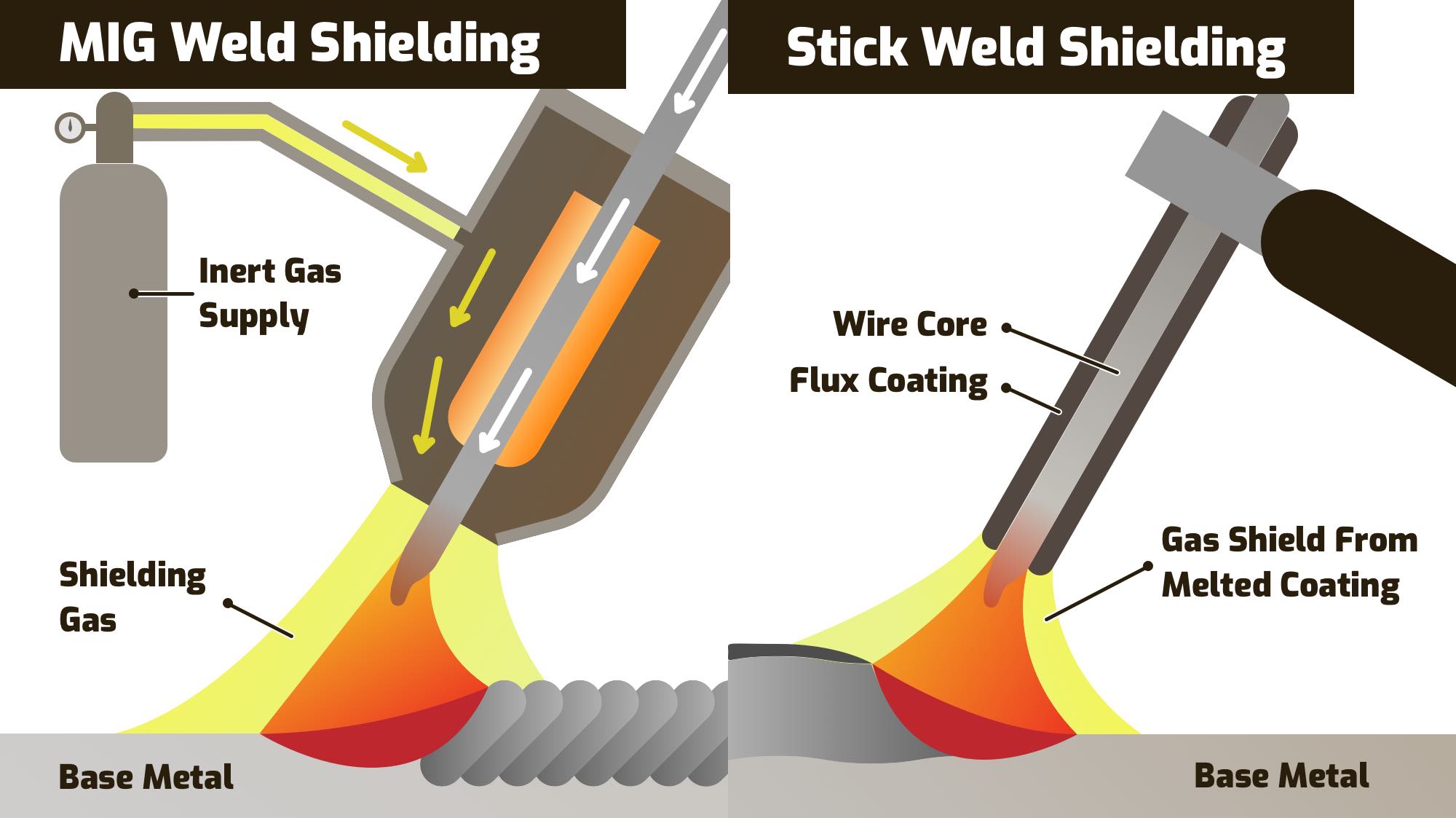

The 2 processes do differ, as arc welding makes use of a flux-core in order to produce shielding gas, while MIG uses a gas source from the outside (external). The arc-welding uses dual-shielded welding that uses an outside (external) gas source that supplements the flux-core which creates a secondary shield.

MIG vs TIG vs Stick Welding UNIMIG Welding Guides & Tutorials

Generally speaking, TIG is more suitable for clean, intricate welds where appearance is paramount ahead of efficiency. MIG is a much easier process but the results aren't quite to the same standard as TIG. Stick is useful for welding rusty metal or welding outside on the farm. There's no "best process" in welding, you have to choose.

MIG vs. TIG vs. Stick vs. Fluxcore Welding YesWelder

Metal Inert Gas (MIG) Welding. Metal Inert Gas ( MIG) welding is a welding process in which an electric arc is created between the workpiece and a solid wire. The wire (filler metal) is continuously fed through the welding machine and into the weld pool to form the weld. The process of MIG welding is semi-automatic, as the machine does all the.

How to Weld Different Metals MIG vs TIG vs Stick vs Flux Core YouTube

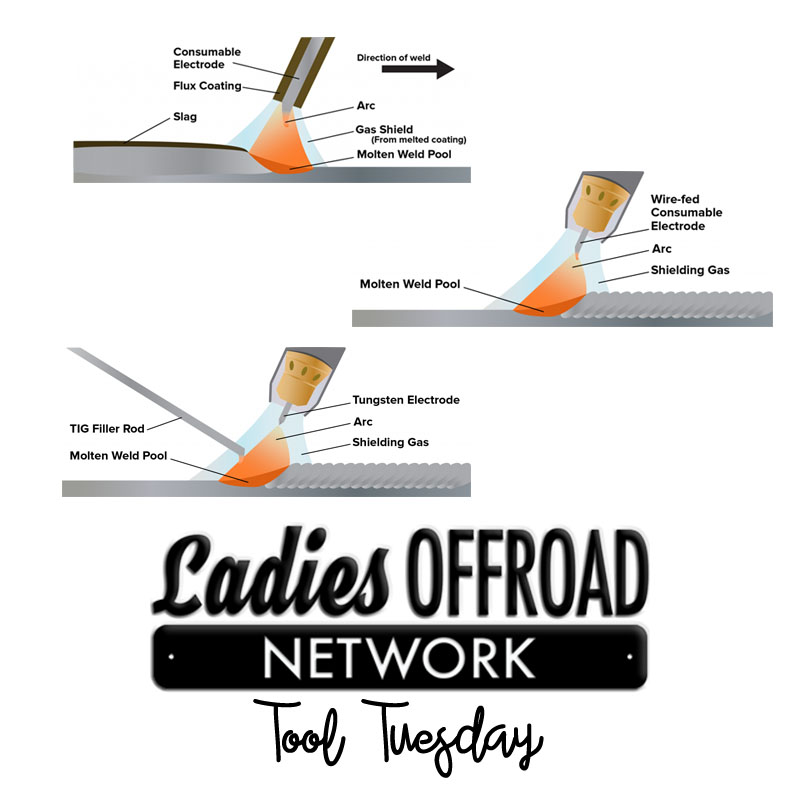

An individual can heat the electrode with the work surface. This mingles and melts with melted portions and forms dirty & quick weld. MIG welding is also considered similar to Stick welding, where it used the electrode instead of stiff. It uses spool-fed electrode wires through the gun. In comparison, a non-consumable electrode is used by TIG.

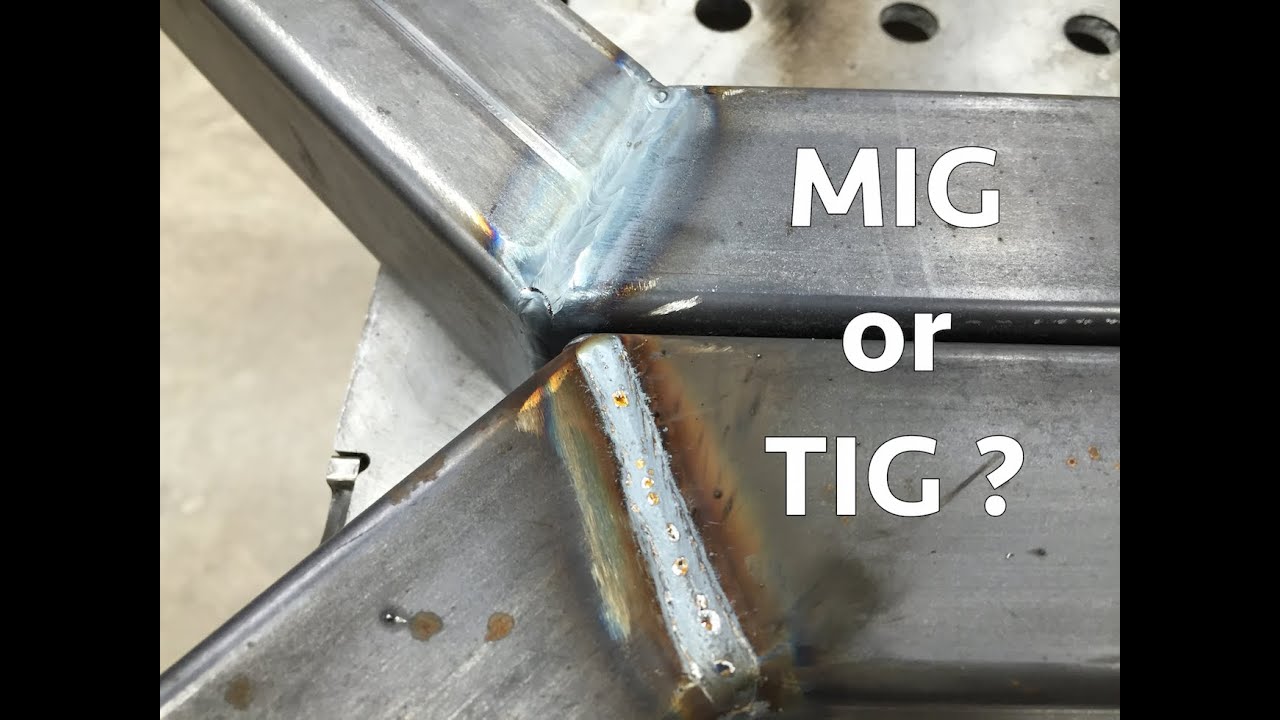

Fabrication Basics // Mig vs Tig Which is Faster? YouTube

MIG vs. TIG welding is a debate that has been going on for decades. Both are types of arc welding commonly used by amateurs and professionals alike.

MIG vs. TIG vs. Stick Welding What Are the Differences? Handyman's World

MIG welding is fast and flexible, great for many projects. TIG welding is all about detail and clean results. Stick welding is easy to learn and really strong. Flux welding is similar to MIG but better for outdoor jobs. We'll help you understand these methods so you can pick the best one for your project.

What Is The Easiest Welding Method? The 12 Correct Answer

The main difference is that with a stick, you can use a variety of different electrodes to create the welds; with MIG, you can only use a wire electrode. Stick welding is cheaper and easier to learn, but MIG welding is more efficient and produces higher-quality welds. TIG (Tungsten Inert Gas) welding is a specialized form of MIG that produces.

Introduction and the pros and cons of Gas, Stick, MIG, and TIG welders

Metal Thickness and Penetration. Stick welding has a better metal penetration rate than MIG welding. By just keeping the arc on, you will need an extra amperage unit for your welding machine. So, if you are going to be working with thick metal and need deep arc penetration for strong joints, go with stick welding.

Best Starter TIG Welder (AC/DC/STICK) TOP PICKS & GUIDE 2023

Metal inert gas ("MIG") welding is in the gas metal arc welding ("GMAW") family of welding. When an active shielding gas is used, it is called metal active gas ("MAG") welding. You can read more on MIG and MAG differences here.. A solid wire electrode is fed from a wire spool to a specialized "gun." Shielding gas supplied from a tank of gas is also fed to the gun.

Comparing Welding Types TIG vs. MIG vs. Stick vs. Arc Tools Haunt

Compared to Stick, MIG requires more knowledge of shielding gases and other parameters such as wire speed. However, it's considered easier to learn than processes like TIG. Often, setting up your machine correctly is the most difficult part. The actual welding procedure is commonly described as "point and shoot.".

MIG vs. TIG vs. Stick Welding What’s the Difference? Schaumburg

TIG is easily the most expensive of all the three methods. The gas, gun and filler metal along with the special tungsten rods are pricier than the other two methods. Not to mention the fact that you have to have a grinder or belt sander to shape the tungsten. MIG is the second most pricey due to the use of gas. Stick is fairly inexpensive.

Welder Interview Questions & Answers Joboilfield

mig vs tig welding. Both MIG and TIG welding use an electric arc to create the weld. However the one big difference between them both is the arc process. MIG welding uses a feed wire that continuously moves through the gun to create a spark. This process melts and this is what forms the weld.

Difference Between Tig And Mig Welding Mig Vs Tig Breakdown My XXX

Additionally, the shielding gas modifies the arc behavior and the transfer of the filler metal to the joint. MIG and TIG use a shielding gas, while stick and flux-cored arc welding processes are gasless. Stick and flux-cored rely on flux which releases the shielding gas while burning to provide the isolated atmosphere around the weld puddle.

Mig vs Tig Welding Ladies Offroad Network

TIG welds are easy to set up, and are available in different amounts of power for heavy pipes and metals or lighter metals. The main differences between MIG welding from TIG welding are power source and settings. MIG welding uses voltage when setting the machine. TIG and arc welding machines use amperage, or "constant amperage power supply.