PCB Repair Training YouTube

A typical technician working on a PCB can generate thousands of volts. SMOS logic devices can be damaged with 250-3000 volts, EPROM devices down to 100 volts, and microprocessor chips as low as 10 volts.

PCB Repair Giz 10p

4.2.2 Conductor Repair, Foil Jumper, Film Adhesive Method R, F, C High A C 4.2.3 Conductor Repair, Welding Method R, F, C High A C 4.2.4 Conductor Repair, Surface Wire Method R, F, C MediumI C 4.2.5 Conductor Repair, Through Board Wire Method R MediumA C 4.2.6 Conductor Repair, Inner Layer Method R, F High E D

Why break a PCB trace plane into multiple parallel traces? Electrical Engineering Stack Exchange

PCB soldering refers to applying solder to printed circuit boards, one of the most common types of soldering. There are various PCB soldering processes, though most typically involve joining components to the PCB surface to create electrical connections. PCB soldering is a vital skill for anyone working with electrical circuits.

Series Circuit Electronic PCB Repair Service, Rs 5000 /number Paras Electronics ID 11375122155

How to Repair Circuit Boards? July 13, 2023 PCB Techniques Will Li Will is proficient in electronic components, PCB production process and assembly technology, and has extensive experience in production supervision and quality control. On the premise of ensuring quality, Will provides customers with the most effective production solutions.

Printed Circuit Board Repair Services Circuit Board Repair

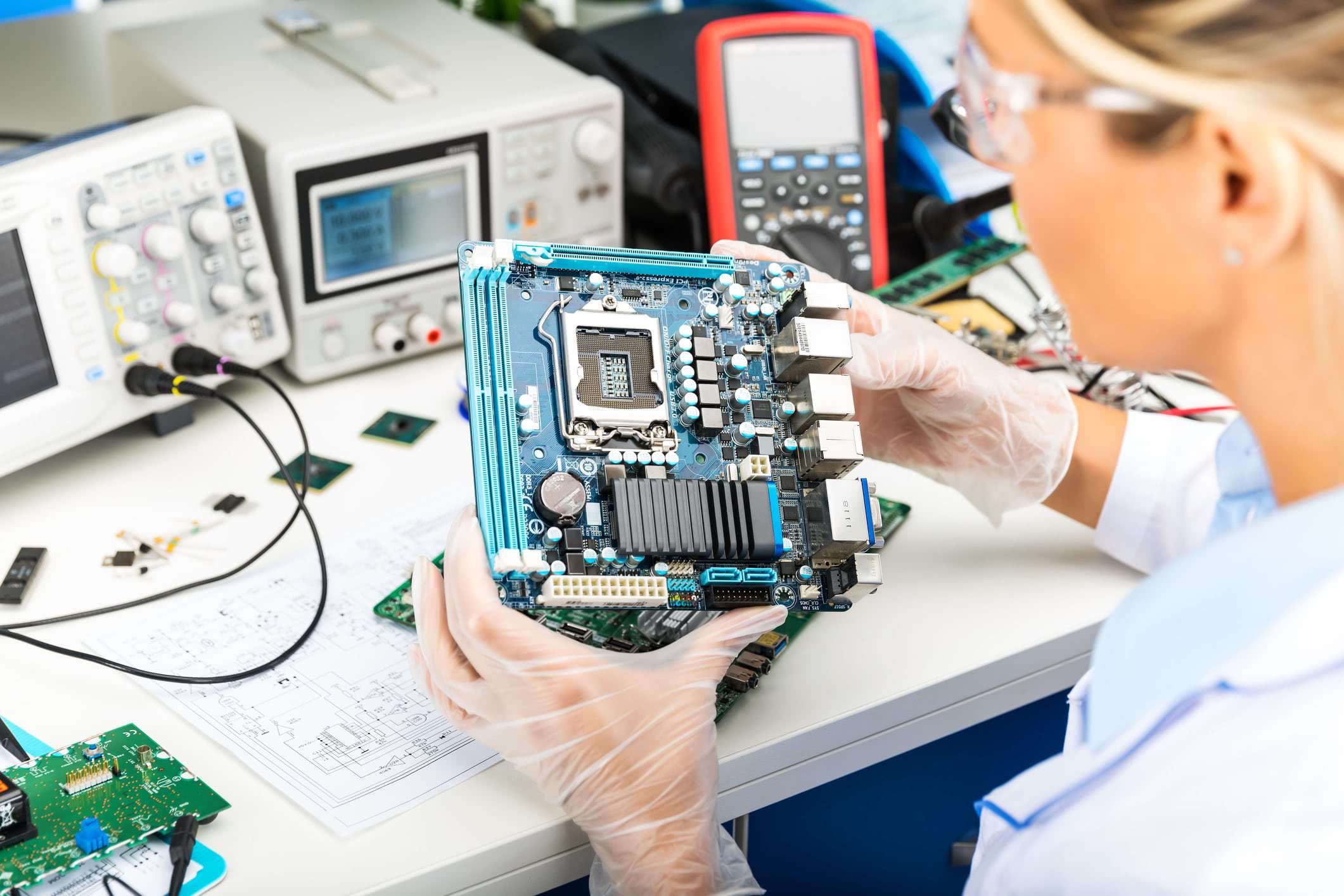

by admin PCB Repair 0 Repairing small circuit boards is not a complex task. Small boards can be simply repaired via applying methodological approaches and using basic tools like oscilloscopes that measure voltages and wave forms at particular test points in the circuit and Digital multimeters (DMMs).

Design considerations for transferring a breadboard prototype to custom PCB

By Sushmitha V December 28, 2022 | 0 Comments Contents By troubleshooting and repairing a PCB, you will extend the lifespan of the circuit, which is both cost-efficient and time-saving. This process may seem like a difficult task, particularly for designs with complex layouts.

PPT PCB Testing and Diagnosing Techniques You Need to Know Before You Get Circuit Board PCB

1.Fix PCB to your work surface then remove the damaged parts. Sometimes, diagnosing a damaged PCB requires an oscilloscope to probe the signal strengths and waveforms at various points to test for continuity of the circuit across the board.

Best Practices for PCB Soldering Techniques VSE

Printed circuit board assembly (PCBA) is a cost-effective hardware device used in mechanical, process, electrical, electronic, military, and medical equipment providing automated and digital functionalities for users. Keeping high quality standards in the PCBA production process is a major challenge for the electronics production industry. Defective PCBAs are submitted to analysis, debug, and.

EE人必練:PCB維修基本功法 電子技術設計

Step 1: Remove the damaged pad or component First, secure the PCB to your work surface so that it doesn't move around while you're working on it. It's best to use tape.

Pcb repair Hobby electronic soldering and construction

Repair Techniques: a. Component Replacement: Identify and replace faulty components such as resistors, capacitors, or ICs. Desolder the defective component and solder a new one in its place. b. Trace Repair: For broken or damaged traces, carefully scrape off the solder mask to expose the trace.

PCB Circuit Repair Machine

Rework is a repair technique that usually involves repairing a PCB that has surface mount components that are not working correctly. The process usually involves the use of special tools such as rework stations and specialized soldering irons. Rework is a complex process and usually requires an expert's help.

PCB Repair 6 Steps Instructables

PCB Damage: PCBs are subjected to collisions, heat, moisture, and chemicals in harsh manufacturing settings, which can lead to cracks, breakage, or corrosion that impair overall functionality. Repair Techniques for PCB Issues. Printed circuit board issues must be resolved with focused repair techniques. The following methods can be used to.

PCB Repair at Rs 2000/piece printed circuit board repairing, pc board repair services, pcb

The 5 Most Common Printed Circuit Board (PCB) Repairs - EMSG 5 Most Common PCB Repairs Many don't realize that the electronics, devices, and items they own are built upon several internal components which work collaboratively to provide the necessary functionality and features they use.

PCB Maintenance and Repair PCB Breakdown Electronic Repair

PCB rework is the process of making changes to or fixing flaws on a printed circuit board after it has already been produced or assembled. This may require anything from changing components to cleaning up excess solder to fixing broken traces or pads.

PCB Repair Kit for repairing most physical damage to a PCBepoxy version

Before applying the mixture of overcoat epoxy, you should clean the cracked area. Some plastic picks are practical to use the epoxy to the PCB crack. The pot life and the tack-free time need to be around 20 min and 30 min, respectively, at 25⁰C. You can cure the cracked circuit board at 100⁰C. For around 10 minutes.

PCB Troubleshooting Tips & Techniques A Complete Guide

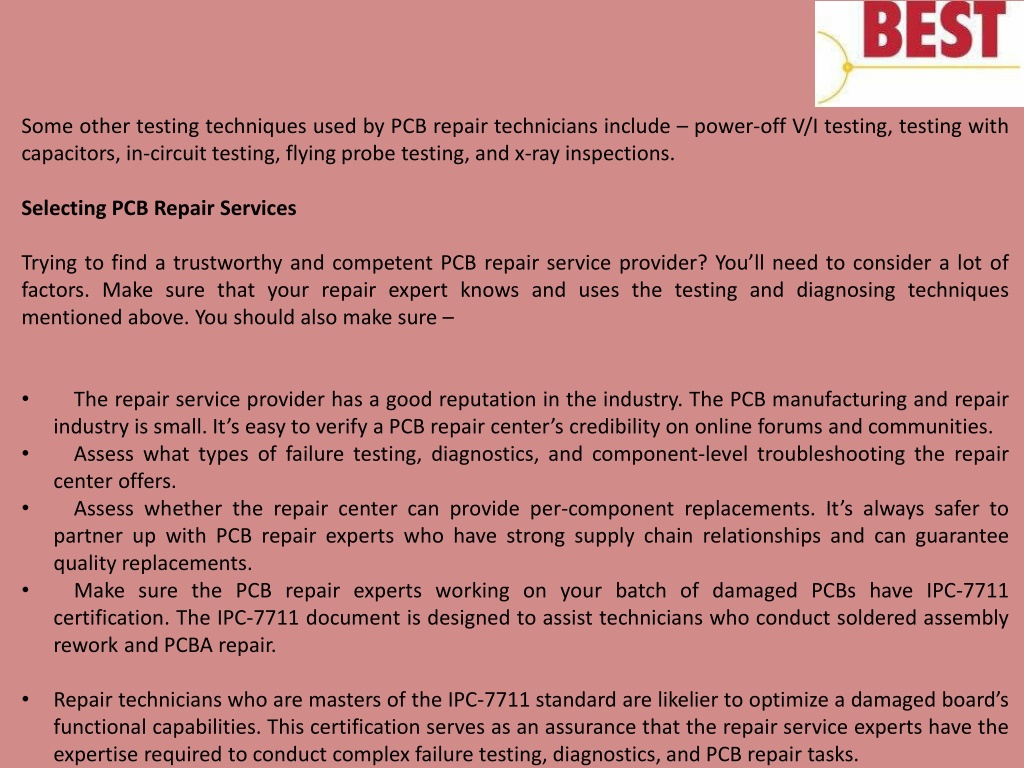

Discover the importance of professional PCB repair services in maintaining the longevity of electronic devices. Explore common PCB issues, the repair process, necessary tools, and the choice between repair and replacement. Learn how to select a reliable repair service and gain valuable DIY repair tips. Ensure the optimal functioning of your electronic devices with expert PCB repair.