Solidworks Tutorial 117 How to Design Spring Friction Clutch Plate by Solidworks Easy Design

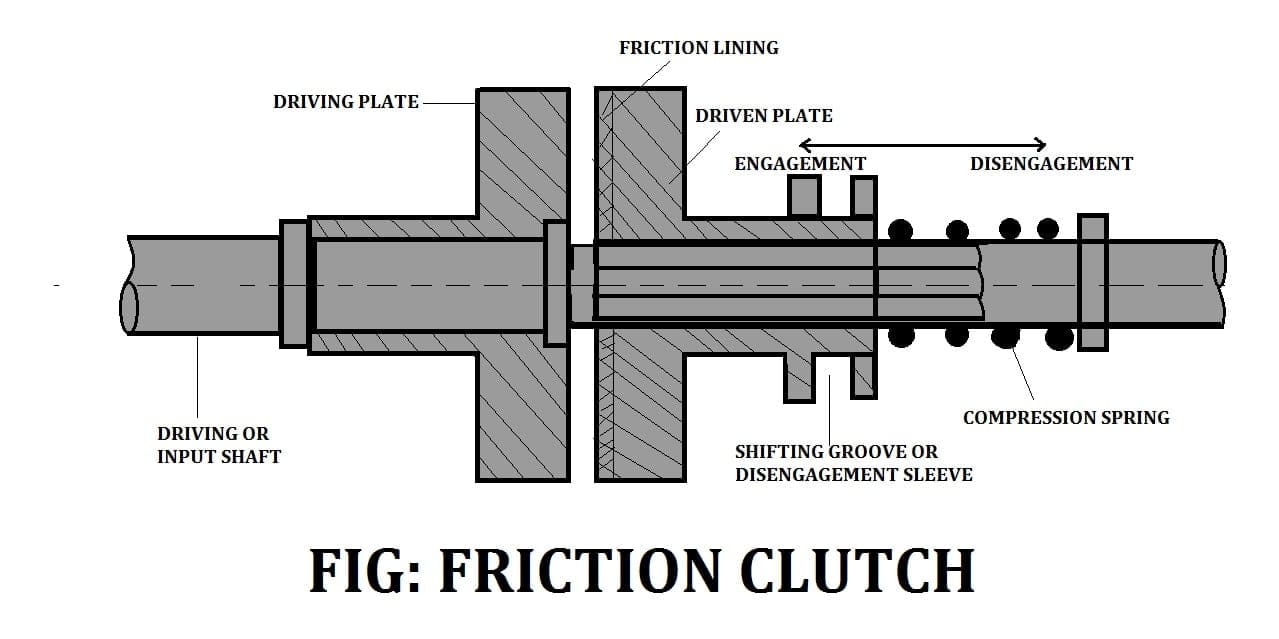

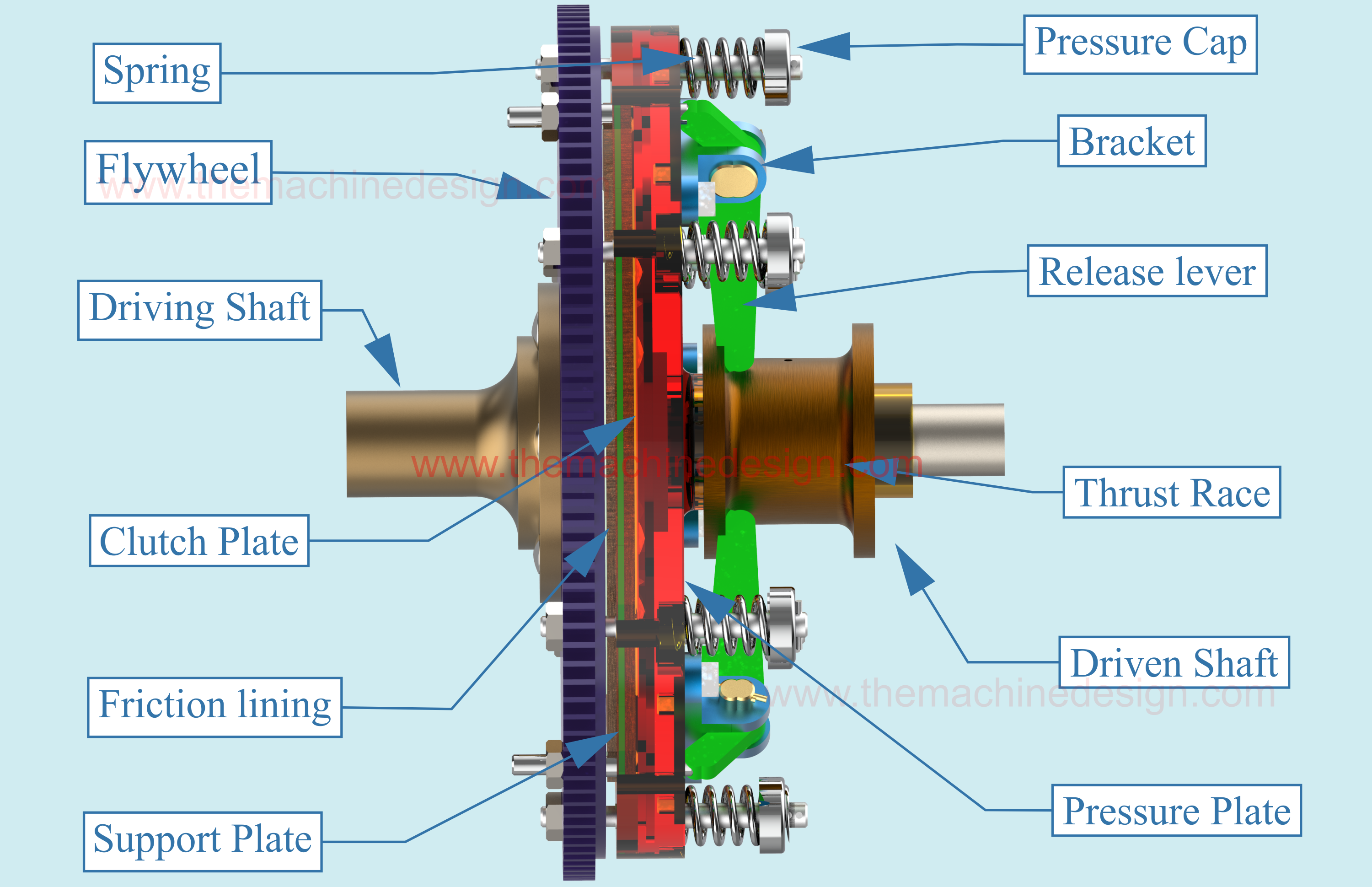

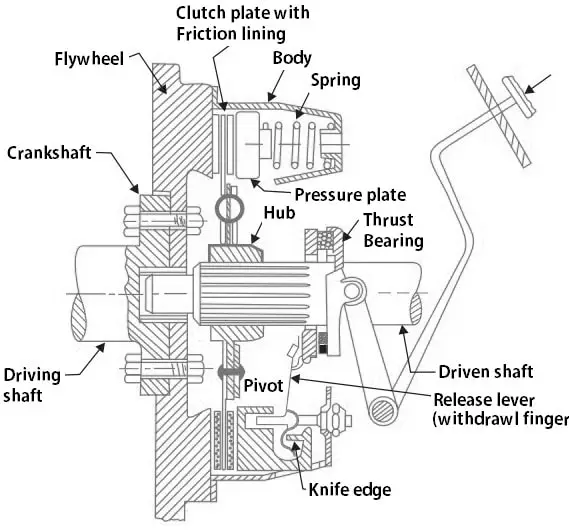

Single plate friction clutch. The parts of a single plate clutch can be seen below .It has only one clutch plate, mounted on the splines of the clutch shaft. This is the most commonly used type. The flywheel is mounted on the crankshaft, and rotates with it. The pressure plate is fixed on the flywheel through the pressure plate is fixed on the.

Sterling Instrument Announces Miniature Inline Slip Clutches that Feature Unique Multiplate Design

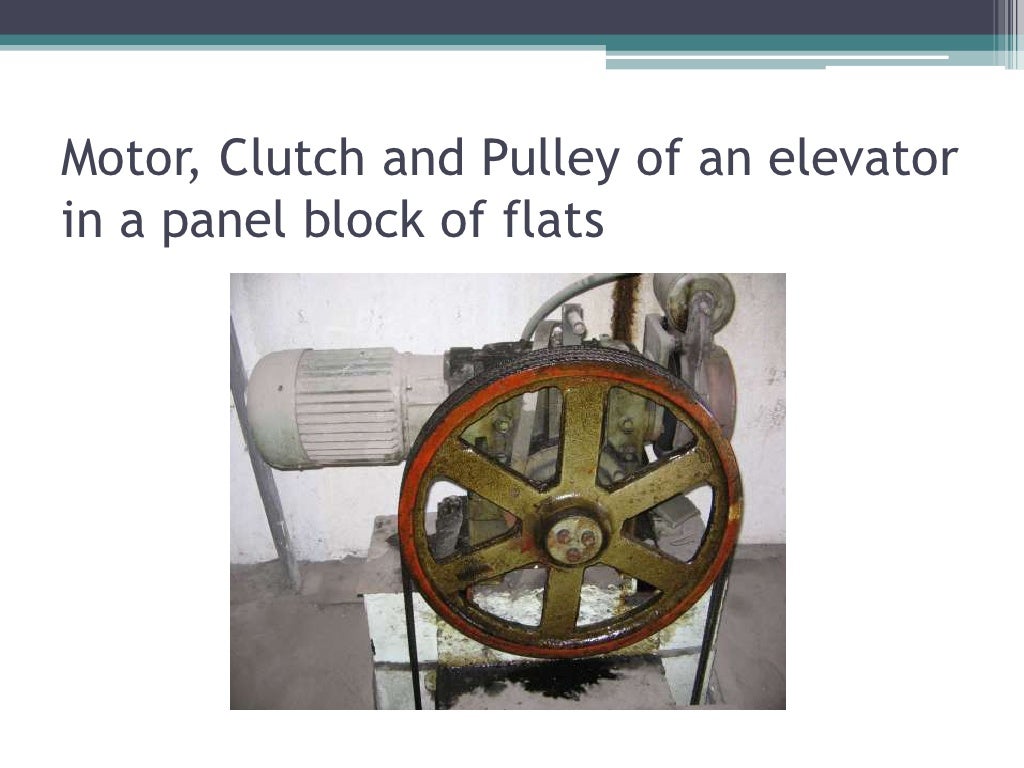

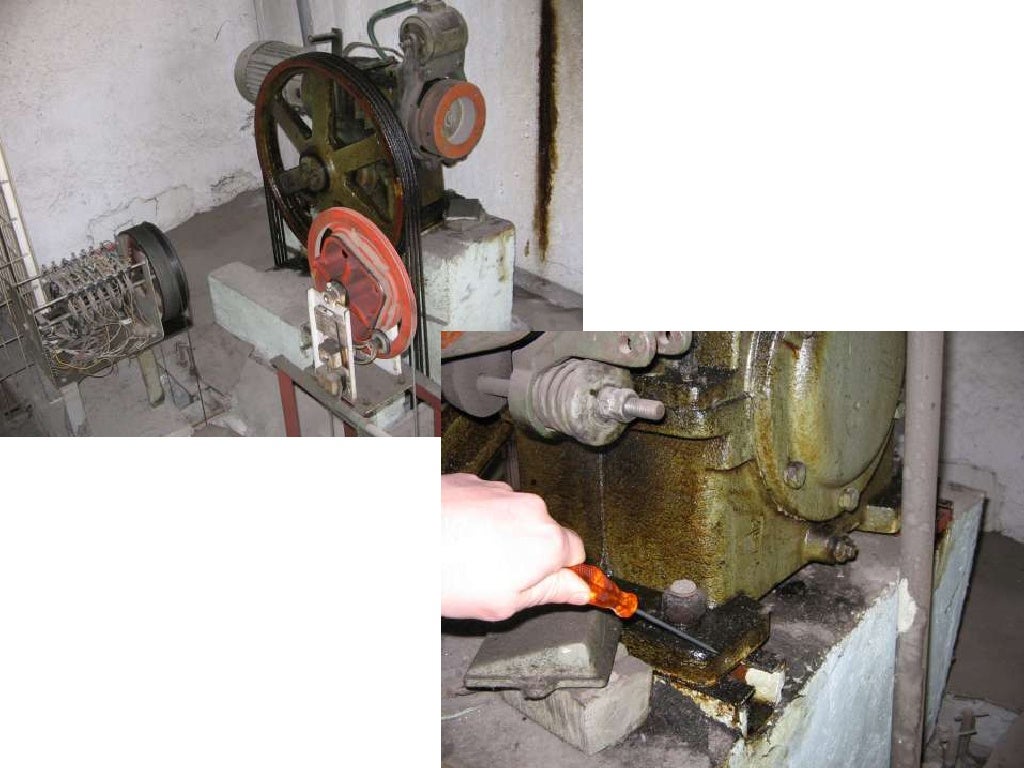

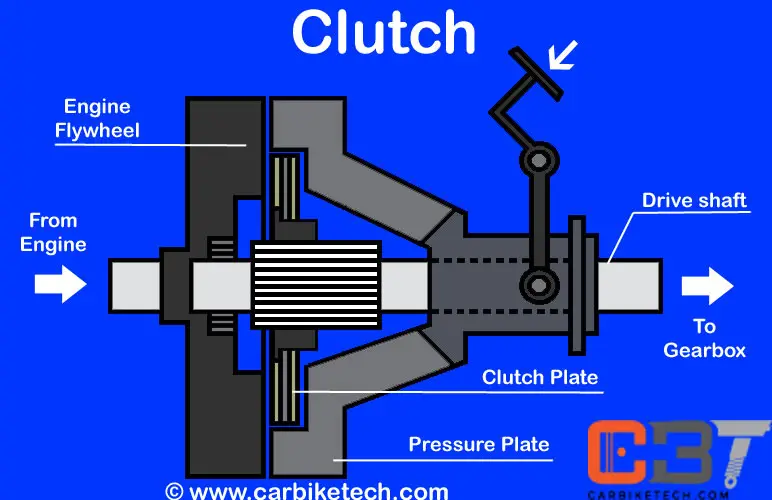

Clutch is a device used in the transmission system of a vehicle to engage and disengage the transmission system from the engine. Thus, the clutch is located between the engine and the transmission system. In a vehicle, the clutch is always in the engaged position.

Friction Clutch Design

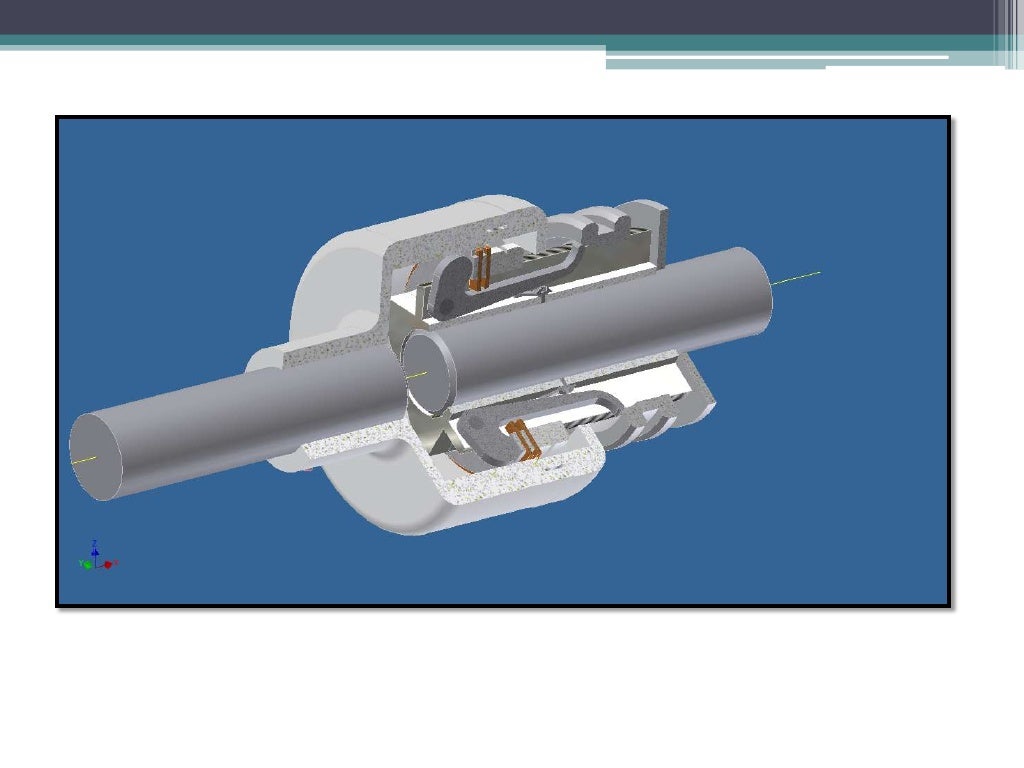

A single plate clutch is designed and modeled using Solid works 2018 software. Static analysis is done on the clutch to determine stresses and deformations using materials Ceramic, cast iron alloy.

Torqmaster Friction Clutch Weasler Engineering, Inc.

S H Sarje. Tate, Ravikiran M., and S. H. Sarje. "Design and Analysis of Clutch Plate for Automatic Single Plate Clutch." IJSRD-International Journal for Scientific Research & Development 3.09.

Single plate friction clutch

Most power transmission components use multiplate friction clutches to provide high power and smooth transmission characteristics; however, noise and vibration are generated by the friction between the clutch disc and plate, potentially decreasing rider comfort.

Walterscheid GmbH Walterscheid® Friction clutch 1316950

Design of single plate clutch T = Torque transmitted µ = Coefficient of friction r 1, r 2 = External and internal radius of contact surface. p = Intensity of pressure W = Total axial load There are two cases, uniform pressure and uniform wear. 1. Uniform pressure theory

Torqmaster Friction Clutch Weasler Engineering, Inc.

Design optimization of friction lining of a clutch plate DOI: Authors: Kartik Virmani VIT University Tanishq Madhogaria VIT University Baskar Ponnusamy VIT University Abstract and Figures.

Friction Clutch Design

These friction surfaces may be: (1) flat and perpendicular to the axis of rotation, as in disc clutch, (2) cylindrical with the normal force in radial direction as in drum clutch or brake, and (3) conical-cone clutches. Often, a cone clutch tends. Get Machine Design now with the O'Reilly learning platform.

Walterscheid GmbH Friction clutch

The method of creating force on pressure plate: Spring clutches (cylindrical, conical, and disc springs) Semi-centrifugal clutches (pressure is created simultaneously by springs and centrifugal forces. Centrifugal clutches. The shape of friction surfaces: Cone (mainly used as a secondary friction devices)

Friction Clutch Design

, P. Baskar Add to Mendeley https://doi.org/10.1016/j.matpr.2021.02.775 Get rights and content Abstract Clutch is a very important part of the proper functionality of the automotive power train, the clutch experiences high pressure, torsional and thermal loads.

Friction Clutch Design

• Gray iron clutch housing and pressure plate: - slip surfaces are controlled to be against iron for efficient heat dissipation and reliable friction coefficient (patented). - fins are incorporated to quickly dissipate heat and isolate it from other components. • Wear-compensating spring: - design allows the clutch friction

Different Types of Clutches Explained in Detail [Notes & PDF]

A friction lock-up connection is created. This allows the engine torque to be directed via the flywheel and the pressure plate to the transmission input shaft. Clutch open When the clutch pedal is pressed, the release bearing is moved against the diaphragm spring load in the direction of the engine.

Single Plate Clutch Working, and Applications. The Machine Design

This study proposes a new design for a friction clutch actuator using the self-energizing principle for vehicle applications such that the power consumption for clutch control is significantly.

Friction Clutch Design

The present work focuses on design and analysis of a friction clutch plate with different materials. Single plate clutch is one of the most essential parts in automobile components. Modelling of the single plate clutch with predefined dimensions was done using CATIA and analysed. Aluminum alloy, E glass epoxy, and ceramic materials were.

Automotive Clutch Characteristics & Types CarBikeTech

This paper presents a simplified friction clutch design, which consists of the dual Belleville spring and the friction plates. This design exploits the preset angle on the Belleville spring to increase the friction area during operation; thus, the load on spring is reduced at a given transmitted torque.

What is a Clutch? Friction Clutch ExtruDesign

Advantages of Friction Clutches: Precise Control: Friction clutches offer precise control over power transmission, making them ideal for applications that require accurate starts, stops, or speed adjustments. Compact Design: Their compact design allows them to be integrated into machinery with space constraints.