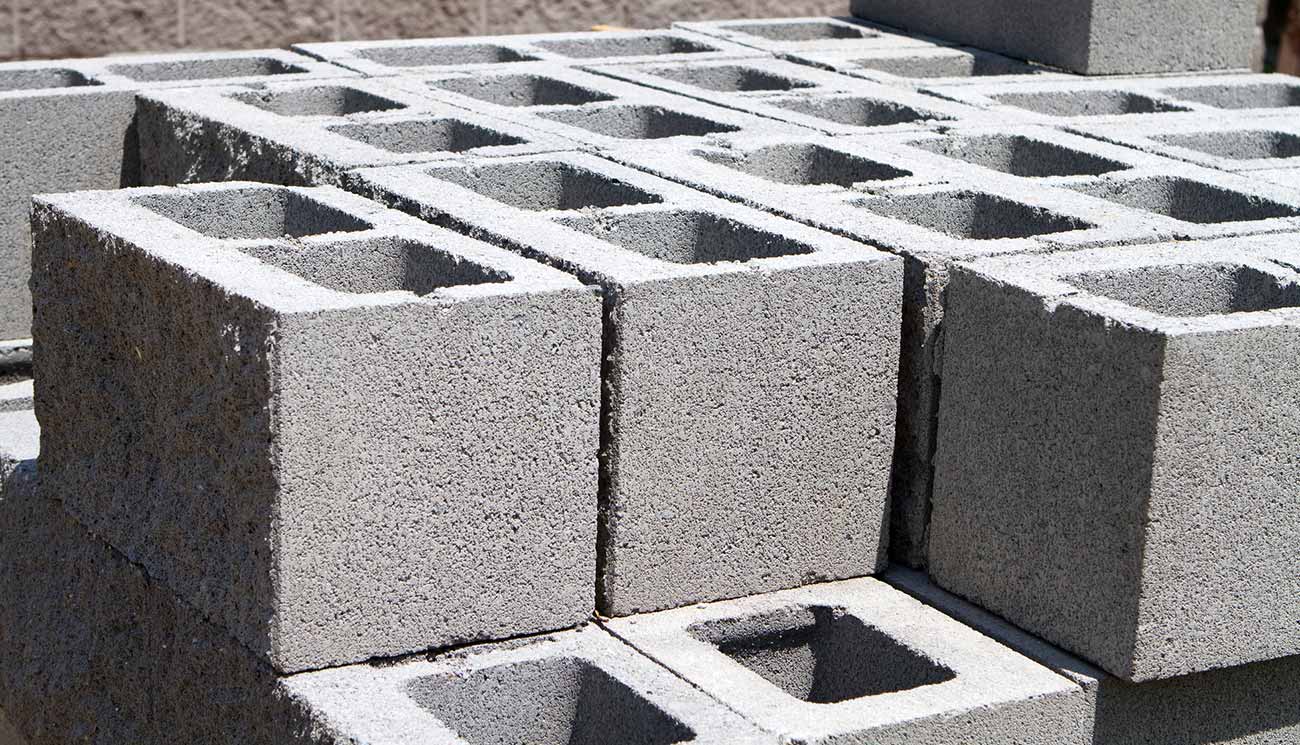

Reinforced concrete blocks stock photo. Image of block 231735110

Reinforced Concrete Block This efficient and economical masonry system allows a single layer of concrete block to serve as the structure and the exposed surface of the wall. Back Recommended Building Types Benefits Special Considerations Definition and Assumptions Regional Variations Fire Rating (hours) Sound Transmission Class (dB)

How To Build CoreFilled Reinforced Concrete Block Walls Structural Reporting

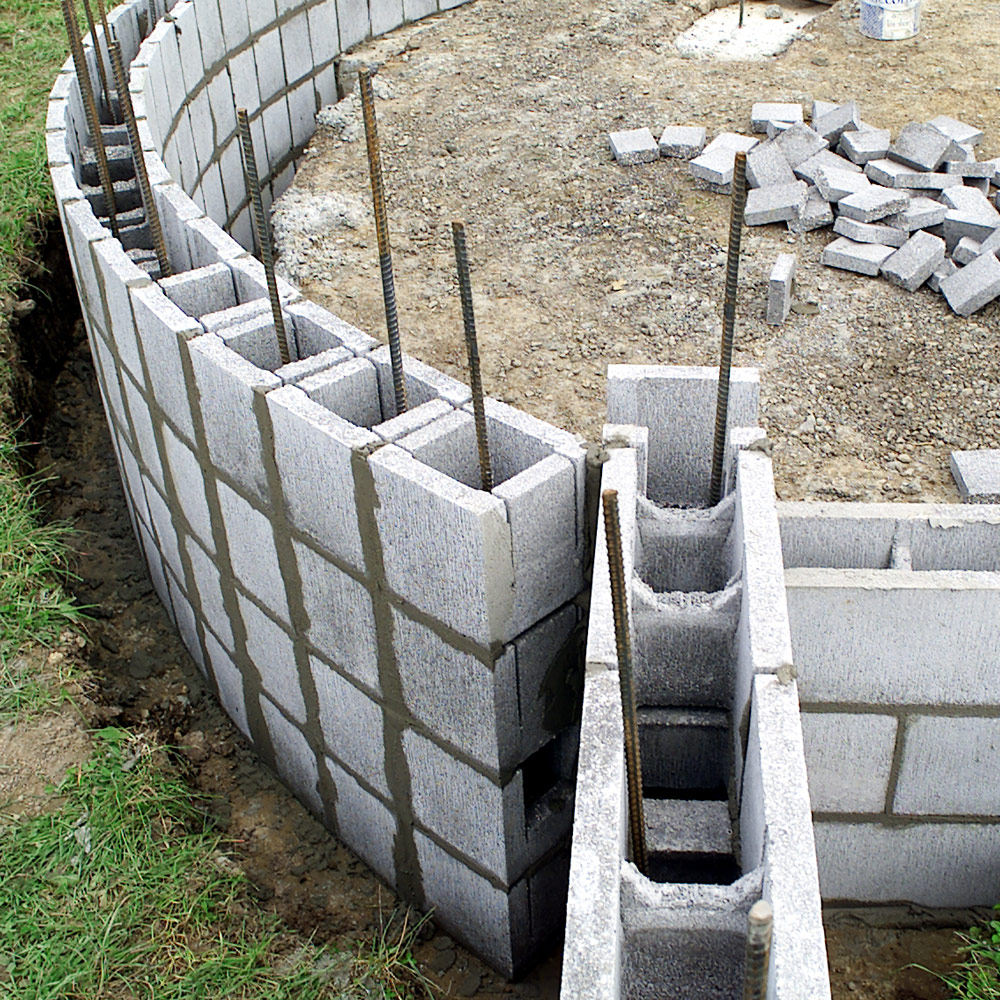

In most cases, vertical reinforcement is positioned towards the interior face of below grade walls to provide the greatest resistance to soil pressures. A solid top course on the below grade concrete masonry wall spreads loads from the building above and also improves soil gas and termite resistance.

CONCRETE BLOCK WALLS The New Zealand's First Passive House

Reinforcement incorporated into concrete masonry structures increases strength and ductility, providing increased resistance to applied loads and, in the case of horizontal reinforcement, to shrinkage cracking. Specifications governing material requirements are listed in Table 1. Table 1—Masonry Material Specifications CONSTRUCTION METHODS

Concrete Masonry Retaining Walls CMU Wall Retaining Wall Companies

A reinforced hollow concrete block column (HBC) and an ordinary reinforced concrete column (RCC) with a cross-section size of 150 mm × 150 mm and a length of 1500 mm were produced using the same materials used for the beams. Moreover, the longitudinal reinforcement was made with 4 reinforcing bars having a 10 mm diameter, while the shear.

Retaining Walls Reinforced Block Walls Island Block & Paving

The absolute necessity for "Clean-out blocks" to be documented on structural drawings for the bottom course of all core-filled, reinforced concrete block walls. A highlighted "Hold Point" note should included on the structural drawing that "The clean-out cavity is inspected by the structural engineer, to ensure it is clear of mortar.

Reinforced Block Retaining Wall 4 Island Block Pavers

= depth of the effective compression block in a concrete beam = name for area = gross area, equal to the total area ignoring any reinforcement = area of steel reinforcement in concrete beam design = area of steel compression reinforcement in concrete beam design = area of steel reinforcement in concrete column design = area of concrete shear st.

Detail of loadbearing reinforced concrete blocks wall under construction Stock Photo Alamy

Units: Lightweight plain gray concrete block (CMU), 8" x 8" x 16" (nom.) Reinforcement: #6 vertical reinforcement at 32" on center 9-gaugejoint reinforcement at 16" o.c. (every other course) flashing: Base flashing and weeps. mortar: Type N, Portland cement /lime, plain gray. Joints: Concave tooled.

concrete blocks reinforced with steel rebar Stock Photo Alamy

Step 1: Lay Four Courses Lay your first four courses (layers) of the concrete block wall. On the fourth course, trowel a skim coat (very thin coat) of mortar on the block. Video of the Day Step 2: Drop the Rebar Hollow concrete blocks have two openings, referred to as cells.

Reinforced Concrete Block Walls Island Block & Paving

The Ivany® Block system is an engineered, reinforced concrete masonry system using the revolutionary and proven Ivany Block. Contact our experts today!

Retaining Walls Reinforced Block Walls Island Block & Paving

From EC2 singly reinforced concrete stress block, the moment resistance capacity of the beam M Rd is given by; M Rd = F c z —— (1) f cd = design strength of concrete = (α cc f ck)/γ c = (0.85 × f ck)/1.5 = 0.5667f ck. Compressive force in concrete = Design stress (f cd) x Area of compression block F c = 0.5667f ck × 0.8 x b = 0.4533bf ck. From the stress block distribution;

Commercial Grey Masonry Firth Concrete Blocks

Description Reinforcing schemes are generally designed to resist tensile stresses in particular regions of the concrete that might cause unacceptable cracking and/or structural failure. Modern reinforced concrete can contain varied reinforcing materials made of steel, polymers or alternate composite material in conjunction with rebar or not.

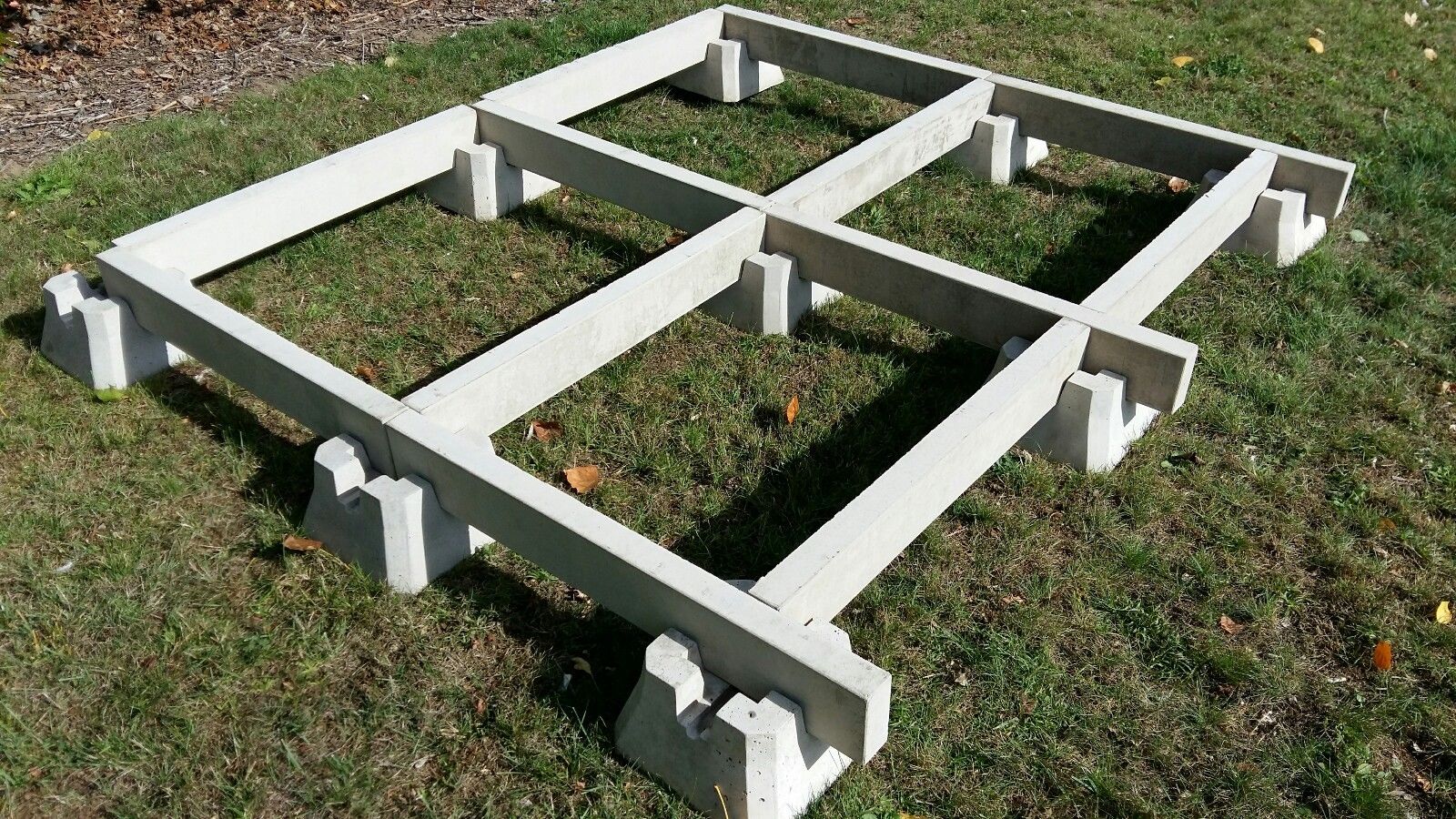

Reinforced concrete foundation blocks concrete products in the construction of the foundation

Otherwise, the best way to reinforce concrete is to install steel rebars or cheaper steel mesh before you pour the concrete. Method 1 Changing Your Concrete Mixture Download Article 1 Alter the cement-to-sand ratio if you're mixing your own cement. Concrete is made by mixing cement and water with other aggregate materials like sand and gravel.

CONCRETE BLOCK WALLS The New Zealand's First Passive House

Reinforced concrete is a combination of traditional cement concrete with reinforcements (steel bar). This combination is made to use the compressive strength of concrete and tensile strength of steel at the same time, hence, work together to resist many types of loading.

CONCRETE BLOCK WALLS The New Zealand's First Passive House

Hollow concrete blocks come in three grades: Grade A has a minimum density of 1,500 kg/m3. Grade B has a density of less than 1,500 kg/m3. Grade C has a density greater than 1,000 kg/m3. Grades A and B are used for load-bearing concrete block walls, while grade C is used for non-load-bearing walls. Hollow blocks come in several types, which are.

EvoCrete The ultralightweight, reinforced concrete blocks revolutionising the gas, mining

The project called for two gable-end reinforced masonry walls that would perform an unusual structural function: provide the support necessary to offset the centerlines of two large masonry chimney flues that traveled as far as 8 feet horizontally from the fireplaces they served. This unique arrangement allowed the chimneys to pass through the.

Reinforced Concrete Beam (Beam & Block System) Wrekin Concrete Products Telford, Shropshire

Fill Hollow Cores The vast majority of concrete block are hollow. When laid on their side and stacked in an offset manner they resemble, to a degree, a honeycomb made by a hive of bees. Bees fill the void spaces of the honeycomb with honey. Your contractor should have filled the hollow spaces in the block with pea gravel concrete and steel bars.