Manufacture and Introduce Asphalt Mixing Plant LB3000

However, since the price of asphalt mixing plant is a company secret and the price is affected by many factors, we can't show you the price directly. However, we will show you the price range of our exported asphalt mixing plants below for your reference. ALQ40-ALQ80: 220,000-370,000. ALQ100-ALQ160: 420,000-560,000.

Continuous Asphalt Mixing PlantHaomei Asphalt Mixing Plant

Asphalt Plant Process. The asphalt plant process is a complex series of steps that involves the handling and storage of aggregates, drying and heating of aggregates, combustion of fuel to heat the drying drum, screening and storage of hot aggregates, mixing of hot aggregates with asphalt binder, and storage and transportation of the finished.

Lintec containerized asphalt batch plants ideal for projects that require the plant to be moved

Advantages of Asphalt Mix Plant. Accuracy- easier to know the amount of mixed asphalt. Costing- It reduces the cost of the project and can be used for the next as well. Time saving-mix is done timely and efficiently. Fewer wastages. Material quality is maintained. Durable. Also Read: Different Types of Concrete Mixer or Concrete Mixing Machines.

Asphalt mixing plant Upgrade a comprehensive construction with low cost

Browse a wide selection of new and used Asphalt Plants for sale near you at MachineryTrader.com. Find Asphalt Plants from BARBER-GREENE, DMI, and WIRTGEN, and. 2023 ADM SPL 110 Portable Asphalt Drum Mix Plant with 4 bin cold feed system, mineral filler silo/ feeding system and 14,000 Gallon asphalt tank. Plant is brand new and available for.

Asphalt Mixing Plants Technobuild

Asphalt Mixing. A thermal mixing process is required to turn aggregates and liquid AC into an asphalt pavement mix for road construction. This makes an asphalt mixing plant necessary for road construction. The complete line of Astec asphalt mixing plants, and its range of capacities and features, gives you the choices and flexibility to create.

Stationary Asphalt Mixing Plant Large Output, Stable Performance

ASPHALT-MIXING PLANTS Ammann batch plants provide the consistency that is crucial to your mix quality. All plant processes and components are carefully developed to ensure that feeding, heating, drying, screening and mixing seamlessly blend together. Helping integrate all the moving parts is the as1 control system,

Asphalt Mixing Plant Setup Cost Things You Should Know

The asphalt plants or asphalt mixing plant is one plant that is used for mixing the dry warm aggregate, padding and asphalt for homogeneous mixture at the required temperature. It is widely used for construction of highways, city roads and parking lots. An asphalt plant is a plant used for the manufacture of asphalt, macadam and other forms of.

Production Process of Asphalt Mixing Plants News & Events Asphalt Batching Plant, Drum

Machines with high compaction output - and asphalt plants that produce high-quality mix - will be on display at the Ammann stand at CONEXPO-CON/AGG 2023. Ammann batch plants provide the consistency that is crucial to your mix quality. All plant processes and components are carefully developed to ensure that feeding, heating, drying.

Asphalt Mixing Plant BUKAKA Road Construction Equipment

With decades of proven experience as a premier asphalt plant manufacturer with a reputation for building high-quality equipment, supported by world-class service, Astec is the ideal partner to our asphalt plant customers. The complete line of Astec asphalt mixing plants, and its range of capacities and features, gives you the choices and.

Asphalt batch mix plant operation Batching plant working

Forced mix asphalt plant. As the name implies, the forced mixing asphalt plant is a kind of equipment that uses a forced mixer to mix asphalt mixture. It is also called asphalt batch mix plant. It is mainly suitable for projects with high requirements on project quality and output, such as municipal roads, graded roads, airport roads, etc.

Asphalt Mixing Plants Technobuild

The medium-size asphalt mixing plant: is the plant that the productivity ranges from 100t to 240t per hour. The large-size asphalt mixing plant: has very strong production capacity that it can produces 320t per hour. 2. Based on the transfer mode divided into: mobile, stationary and semi-stationary asphalt mixing plant

Manufacture and Introduce Asphalt Mixing Plant LB5000

CONTINUOUS ASPHALT MIXING PLANTS. Related News. Retrofit Transforms Non-Ammann Plant from Idle to Productive. 21/09/2023. J. Charoen Subanan Co. Ltd. valued its Ammann JustBlack 120 Asphalt-Mixing Plant since acquiring it in 2015. Read More. Sustainability and Early Success at New Factory in China.

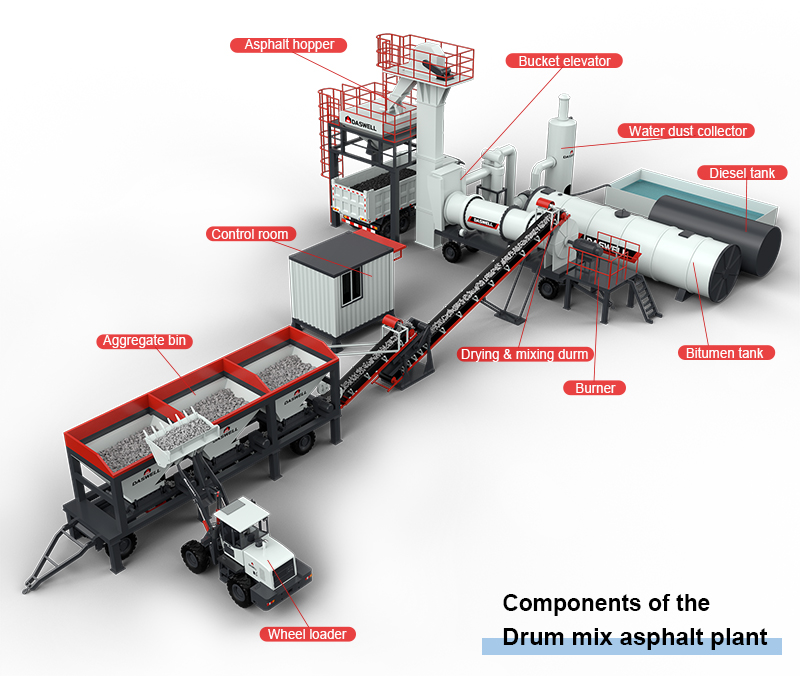

What are the Different Types of Asphalt Mixing Plant? DASWELL

Asphalt mix plants are generally categorized as batch mixing plants, which produce a series of batches of asphalt and continuous mixing plants (these are generally of the drum mixing type), which produce a continuous flow of asphalt. This categorization reflects not only the mode of production but also highlights different quality control needs.

Asphalt Mixing Plants Technobuild

Asphalt mixing plant, also known as asphalt concrete mixing station, refers to a complete set of equipment used for mass production of asphalt concrete, which can produce asphalt mixture, modified asphalt mixture, and colored asphalt mixture. It is a necessary equipment for roads, airports, ports.

How to select qualified asphalt mixing plant

Asphalt plants are typically shut down in the winter because the production of hot-mix asphalt requires high temperatures that cannot be maintained in cold weather. The cold temperatures also make it difficult to transport the asphalt to construction sites, where it needs to be laid down while it is still hot and pliable.

LB2000 Asphalt Mixing Plant with Integrated Finished Silo China Fixed Asphalt Mixing Plant and

ASPHALT-MIXING PLANTS Ammann offers batch and continuous plants to ensure customers have the method that works best for them. Both options provide the consistency that is crucial to your mix quality. All plant processes and components are carefully developed to ensure that feeding, heating, drying, screening and mixing seamlessly blend together.